Automated Storage and Retrieval Systems (ASRS) are designed to operate in a variety of environments, including cold storage facilities. However, certain considerations need to be taken into account when implementing ASRS in cold storage environments. Here are some considerations for ASRS operation in cold storage environments:

Equipment Selection: When choosing ASRS for a cold storage environment, it is important to select equipment that is designed to operate in low temperatures. Components such as motors, sensors, and controllers should be able to withstand the cold conditions.

Material Handling: The ASRS system should be capable of handling materials that may be affected by cold temperatures, such as frozen goods. Specialized equipment like cold storage cranes or conveyors may be required.

Safety Precautions: Cold temperatures can affect the operation of machinery and equipment. Regular maintenance and inspections are necessary to ensure the safe operation of the ASRS in a cold storage environment.

Energy Efficiency: Operating in cold storage environments may require additional energy to maintain the low temperatures. Energy-efficient designs and optimizations can help reduce energy costs.

Regarding maintenance requirements for ASRS, typical maintenance tasks include:

Regular Inspections: Routine inspections of the equipment to identify any signs of wear and tear, damage, or malfunction.

Cleaning and Lubrication: Cleaning components and ensuring proper lubrication of moving parts to prevent friction and wear.

Software Updates: Keeping the control software up to date to ensure optimal performance and compatibility with other systems.

Emergency Procedures: Developing and practicing emergency procedures to address any malfunctions or breakdowns in the system.

Training: Training staff members on how to operate and maintain the ASRS system effectively to prevent issues and address minor problems promptly.

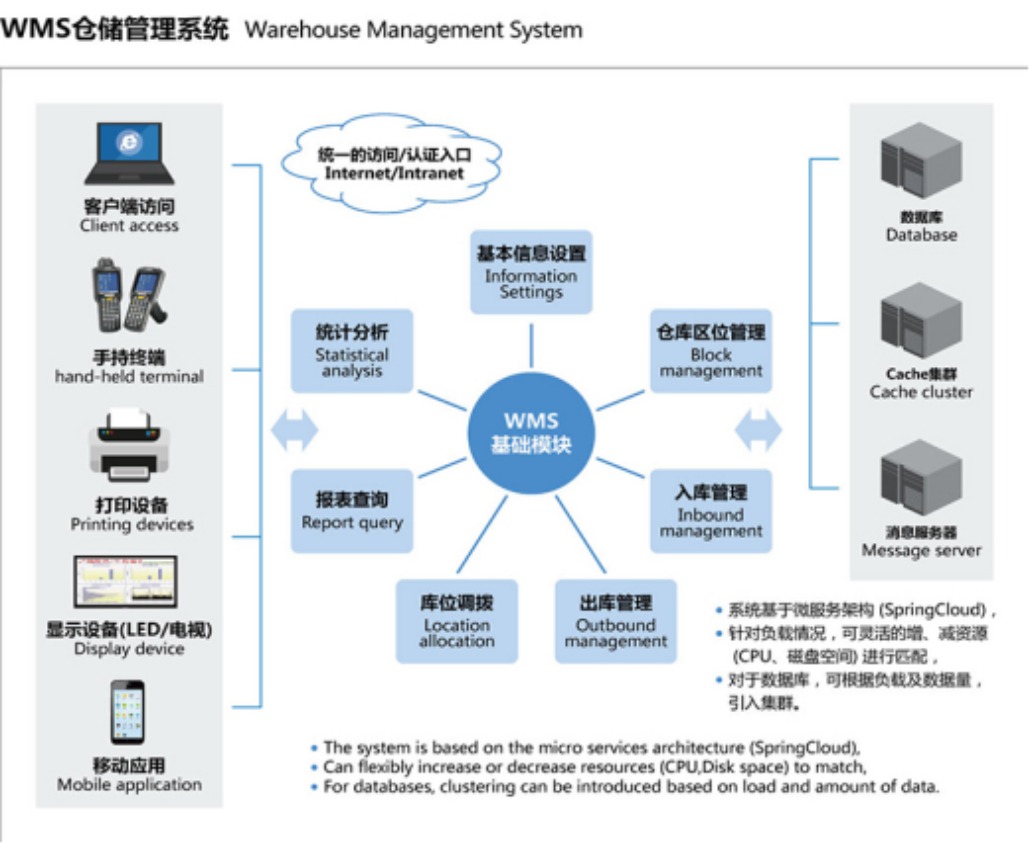

Integrating an ASRS with Warehouse Management Systems (WMS) or Enterprise Resource Planning (ERP) systems is vital for optimizing warehouse operations. Here are some ways in which ASRS can be integrated with WMS/ERP systems:

Data Exchange: ASRS can be integrated with WMS/ERP systems to exchange information such as inventory levels, order status, and storage locations in real-time.

Order Processing: WMS/ERP systems can send instructions to the ASRS for order picking, replenishment, and storage tasks based on inventory data and customer orders.

Tracking and Reporting: Integration allows for tracking of inventory movements, performance metrics, and real-time reporting across the warehouse.

Optimization: WMS/ERP systems can optimize inventory placement within the ASRS to improve efficiency in picking, storage, and retrieval processes.

Automated Workflows: Automated workflows can be set up between the ASRS and WMS/ERP systems to streamline operations and reduce manual intervention.

By integrating ASRS with WMS/ERP systems, businesses can achieve improved inventory accuracy, efficient order fulfillment, and enhanced overall warehouse productivity.

Add: NO.409 West Jianshe Road, Economic Development Zone, Jinhu County, Jiangsu Province, China

Copyright 2026@ Jiangsu Kingmore Storage Equipment Manufacturing Co., Ltd All Rights Reserved.

Sitemap

| Blog

| Xml

| Privacy Policy

Network Supported

Network Supported