Products

Four-way Shuttle Rack System

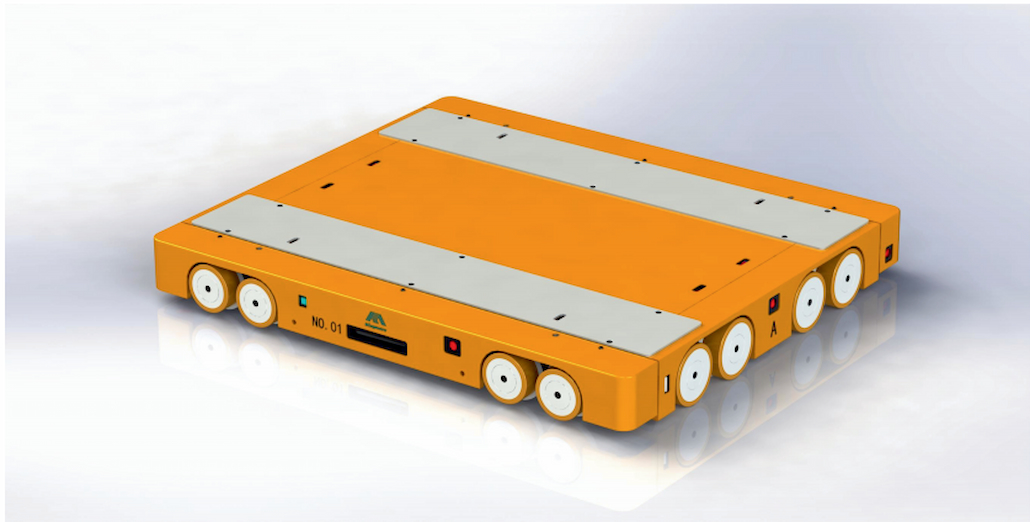

Kingmore Four-Way ShuttleThe four-way shuttle system is an intelligent handling equipment that combines lateral movement with vertical pallet lifts to automate storage, retrieval, and transportation tasks.

Guided by the instructions from the Warehouse Management System (WMS) or Warehouse Control System (WCS), the radio shuttle car can autonomously pick up and deliver pallets to designated locations within the racks, enabling seamless automated storage and retrieval of goods in the warehouse.

The four-way shuttle radio car moves laterally and cooperates with the pallet lift’s vertical movement to achieve the purpose of storage automation. Through programming, tasks such as storage, retrieval, and transportation can be realized. With high adaptability and flexibility, the system can adjust operating lanes and shuttle numbers as needed for efficient operation, providing versatile project layout options. A conveyor line is positioned in front of the racking system to facilitate the picking and receiving of pallets. An elevator is employed to transport both the radio shuttle and pallets to various levels within the warehouse.

Parameter

Parameter specification of the four-way shuttle radio car

|

NO |

Parameter specification |

Details |

|

1 |

Available pallet specifications |

W1200*D1100mm |

|

2 |

Pallet type |

“川”shaped pallet, “田”shaped pallet |

|

3 |

Pallet weight |

Max=1500kg |

|

4 |

Self weight of device |

350kg |

|

5 |

Running speed at empty load{Main track/sub-track) |

70/58 m/min |

|

6 |

Running speed at full load(Main track/sub-track} |

48/36 m/min |

|

7 |

acceleration |

Maximum acceleration 0.2m/s² |

|

8 |

Traveling drive motor |

DC48V |

|

9 |

Jacking motor |

DC48V |

|

10 |

operating ambient temperature |

0~45° |

|

11 |

Program controller |

SIEMENS PLC |

|

12 |

Control loop voltage |

DC48V |

|

13 |

Power energy |

lithium battery |

|

14 |

Battery charge and discharge times |

More than 1000 times |

|

15 |

Communication mode |

Industrial remote control 433MHz/WiFi 2.4/5.8ghz |

|

16 |

Remote control mode |

Wireless remote control |

|

17 |

Braking mode |

Servo motor, servo controller |

Parameter specification of the pallet lift

|

NO |

Parameter specification |

Details |

|

1 |

Pallet specifications |

W1200*D(1000-1200)mm |

|

2 |

Equipment dimensions |

2700*1700mm |

|

3 |

Load |

1500kg |

|

4 |

Lifting speed |

30m/s |

|

5 |

Acceleration |

0.3m/s² |

|

6 |

Working voltage |

Three-phase 380V 50Hz |

Core Functions

The four-way shuttle system is mainly used for the automatic handling and transportation of pallet goods in the warehouse. Automatic pallet shuttle can realize automatic storage and retrieval, automatic lane and layer change, intelligent leveling and automatic climbing. 4-way shuttle is not constrained by locations, roads, or slopes and can be utilized on the ground or on the shelf track to reach any point in the warehouse, which is a piece of automated handling equipment with integrated intelligent control, unmanned guiding, and other features.

Features

(1)The 4 way pallet shuttle can flexibly adjust the working lane of the shuttle and cooperates with the pallet lift to achieve automatic access to goods, automatic lane changing, intelligent leveling and automatic climbing, directly reaching any location in the warehouse.

(2)The four-way shuttle system can improve storage space utilization. Not only can it operate in four directions on the arranged shelf track, but it can also use a vertical lift to perform layer-changing operations, further increasing the flexibility and scalability of warehouse racking layout.

(3)The four-way shuttle system greatly reduces the workload of warehouse personnel, provides the possibility for unmanned work in the warehouse. It is especially suitable for cold storage, warehousing toxic goods and other unsafe areas.

Applicable scenarios

The four-way shuttle system is suitable for picking scenarios, especially in the field of cold chain logistics. Traditional cold storage not only has low space utilization, but also has poor operation efficiency. But the pallet shuttle can greatly increase the storage density and improve the working environment. And pallet lifts can speed up the incoming and outgoing operations of materials, reduce the waste of manpower and time, and improve the efficiency of the entire warehousing system so that the whole system can quickly transport heavy equipment and bulk cargo and store them in the right location.

Add: NO.409 West Jianshe Road, Economic Development Zone, Jinhu County, Jiangsu Province, China

Copyright 2026@ Jiangsu Kingmore Storage Equipment Manufacturing Co., Ltd All Rights Reserved.

Sitemap

| Blog

| Xml

| Privacy Policy

Network Supported

Network Supported